In 2019, the news of 5G is endless, or the operator is launching a large-scale test, or the terminal manufacturer is releasing a 5G mobile phone. South Korea officially launched the 5G service for the public recently, It is also announcing the opening of the 5G commercial screen.

5G commercialization brings unlimited market opportunities to upstream and downstream industries. As a key interconnect for assembling electronic components, how will PCB be in the 5G market? Is the technical requirements of 5G for PCBs unattainable? Can domestic PCB companies borrow 5G opportunities to achieve cornering overtaking?

5G provides a huge market for PCB

PCB is called “the mother of electronic products”, not only provides electrical connections for electronic components, but also carries digital and analog signal transmission, power supply and RF microwave signal transmission and reception functions of electronic devices, most electronic devices and Products require PCBs.

It is understood that every 1 RMB of PCB can support the development of 30 RMB terminal products. The 5G era has provided a huge market and opportunity for the PCB industry. According to estimates, the direct output economic benefits of 5G in 2020, 2025 and 2030 are 484 billion RMB, 3.3 trillion RMB and 6.3 trillion RMB respectively. The economic benefits of output were 1.2 trillion RMB, 6.3 trillion RMB and 10.6 trillion RMB respectively.

5G from the communication network construction, to the terminal, to the derivative application scenarios, all put a lot of demand on the PCB. In 5G wireless base stations, bearer networks, transmission networks, and core network hardware facilities, the application of PCB hardware will be greatly increased, such as 5G RF boards, backplanes, high-speed stencils, server boards, microwave boards, power boards, etc.

5G requires comprehensive improvement of PCB technology

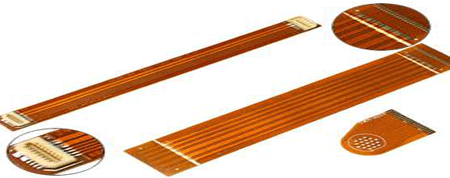

While 5G brings opportunities to the PCB industry, it also puts higher and more stringent requirements on technology. Its indicators in terms of speed, integration, heat dissipation, frequency and multi-layering are much higher than 4G. spectrum intervention, Massive MIMO and ultra-dense networks will be the core technology for implementing 5G networks. Correspondingly, technical challenges have also been raised for PCBs.First, the base station radio unit and antenna have undergone major changes in structure and function, mainly because the number of radio unit channels increases (8 channels rise to 64 channels), corresponding PCB area increases; 4G base station equipment RRU plus antenna unit The structure is changed to a 5G AAU structure (integrated with RRU and antenna functions), which corresponds to a higher degree of PCB integration. Secondly, in order to achieve ultra-dense network coverage, in addition to spectrum applications below 6 GHz in the 5G spectrum, 28G, 39G and other millimeter-wave spectrum resources for hotspot coverage and high-capacity high-speed transmission will be widely used. Therefore, high-frequency microwave base stations The demand for high frequency PCBs will increase. Finally, under the network architecture of 5G independent networking, in order to meet the technical requirements of high-speed transmission, the PCB required for data transmission equipment such as baseband unit, network board, backplane, server, etc. will use higher-level high-speed copper clad material. . These technical challenges require domestic PCB companies to keep abreast of technology and market trends and take a differentiated path in order to build a unique competitive edge.

In addition, thermal management of PCB products may be particularly important in the future. “There is not only the reason for adapting to high-frequency devices, but also the heat dissipation requirements brought by high power and high power density. The application of new high thermal conductivity materials, special heat dissipation structure type PCB requirements will appear.

Gain insight into customer needs and take the road to differentiation

With the rapid development of the electronic information industry, the PCB industry continued to grow. The global PCB output increased from more than 40 billion US dollars in 2008 to 60 billion US dollars in 2018. The global share of China’s PCB industry has also changed dramatically, from less than 10% in 2000 to 30% in 2018 and over 50% in 2018.

Different from the OEM manufacturing of standard products, PCB is a customized product for downstream customers. It is a highly “customized” product, which requires a deeper understanding of customer needs. 5G is a technology that is constantly developing and constantly innovating. If you can’t keep up with the needs of customers, it is difficult to make progress with the market by making more thorough and detailed research on products. He also stressed that technical communication with raw material enterprises should be strengthened. Many products in the 5G era have high requirements for raw materials and production processes. Only domestically able to establish a good raw material supply system can be done steadily and quickly in the field of 5G PCB. Bigger and stronger. Su Xinhong, deputy director of the PCB Research Institute of Zhuhai Founder Printed Circuit Board Development Co., Ltd., said that companies that use printed circuit boards for communication equipment need to study high-speed materials applications to study signal integrity and signal simulation. At the same time, high-speed material process research is needed, and corresponding equipment upgrades are required to meet the requirements for improved circuit board processing accuracy.