How many types of flexible circuit boards are there?

At present, flexible circuits mainly have four types of single-sided FPC, double-sided FPC, multi-layer FPC and rigid flexible circuit boards.

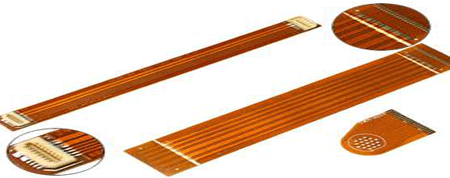

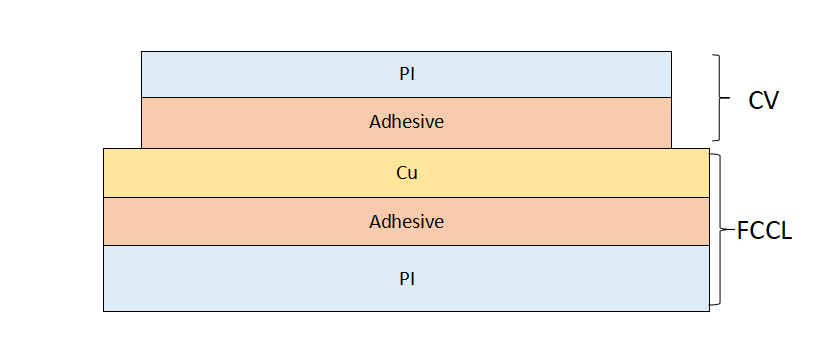

1. Single-sided flexible PCB

Single-sided flexible board is the lowest cost, when the board is not required for high electrical performance. For single-sided wiring, a single-sided flexible board should be used. It has a chemically etched conductive pattern, and the conductive pattern layer on the surface of the flexible insulating substrate is a rolled copper foil. The insulating substrate may be polyimide, polyethylene terephthalate, aramid fiber ester and polyvinyl chloride.

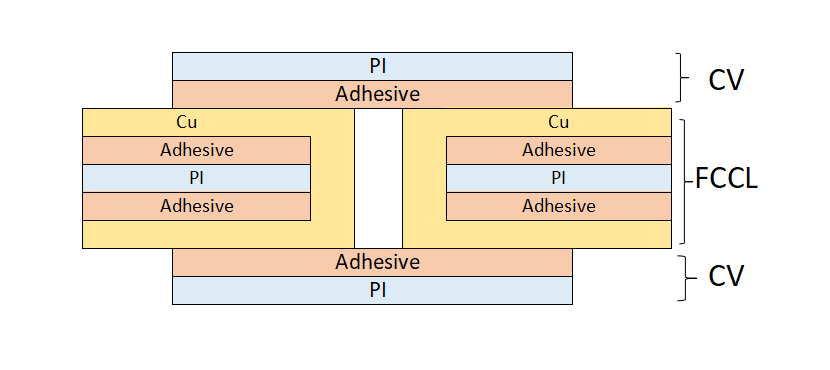

2. Double-sided flexible PCB

Double-sided flexible board is a conductive pattern made by etching each layer on both sides of the insulating base film. The metallized holes connect the patterns on both sides of the insulating material to form a conductive path to meet the design and use functions of the flexibility. The cover film protects the single and double-sided wires and indicates where the components are placed.

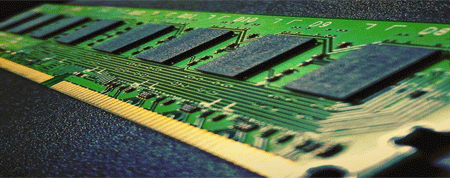

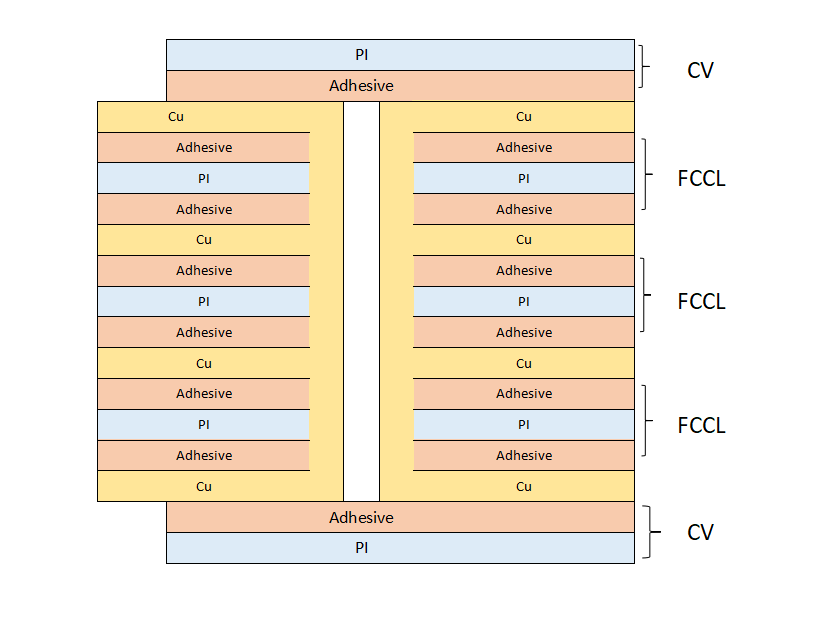

3 Multilayer flexible PCB

Multilayer flexible board is a single-sided or double-sided flexible circuit of 3 or more layers laminated together, and a metallized hole is formed through a drill collar L and electroplating to form a conductive path between different layers. This eliminates the need for complex welding processes. Multilayer circuits have tremendous functional differences in terms of higher reliability, better thermal conductivity, and more convenient assembly performance. When designing the layout, the interaction between assembly size, number of layers, and flexibility should be considered.

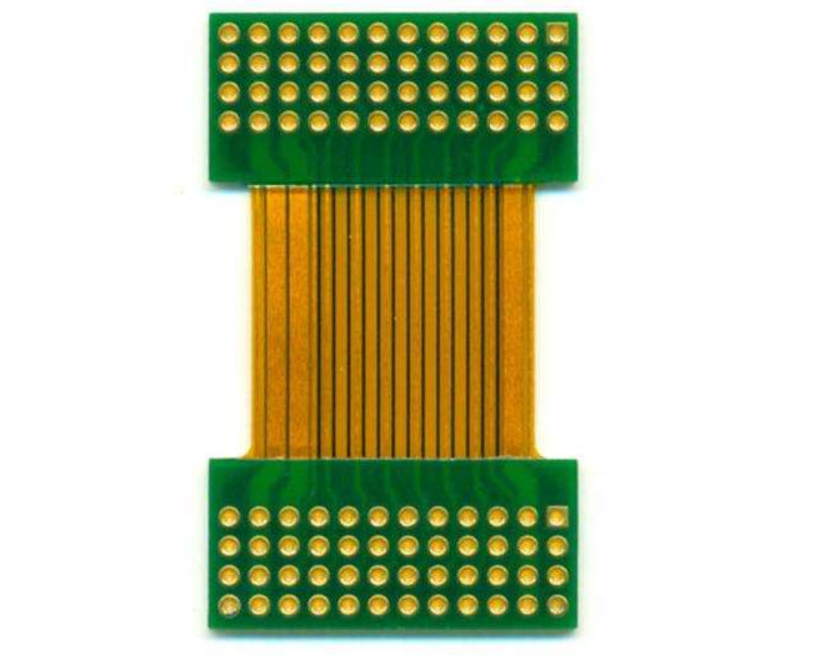

4. rigid flexible PCB

Conventional rigid flexible sheets are composed of rigid and flexible substrates that are selectively laminated together. The structure is tight, and the metallized 孑L forms an electrically conductive connection. If a printed board has components on both the front and back sides, a rigid flexible board is a good choice. But if all the components are on one side, it is more economical to use a double-sided flexible board and laminate a layer of FR4 reinforcement on the back.

HDI rigid-flex board: High Density Interconnection (HDI) Rigid-flexible printed circuit board is a high-end printed circuit board product. Its goal is to meet the miniaturization, high-frequency and high-speed electronic products. The need to grow towards growth. The HDI rigid-flexible combination board combines the advantages of the popular HDI board and the rigid-flexible joint board, and promotes the high integration and high-intelligence growth of the electronic system design and production. It has been widely used in high-end technologies such as aerospace technology, medical equipment and expenses. In the electronic product.